Electromagnetic Wave Shielding Plating Process for PPS

TOP EP PROCESS

The rapid proliferation of smartphones, Wi-Fi devices, and autonomous driving technologies has led to a significant increase in the use of electromagnetic waves in recent years. As a result, controlling electromagnetic interference to prevent malfunctions and failures is more critical than ever.

PPS (polyphenylene sulfide) is a high-performance engineering plastic known for its excellent heat and chemical resistance. It is widely used in electronic devices and automotive parts that must operate in high-temperature and high-stress environments. However, to shield the electromagnetic waves, a thin metal film needs to be formed on the surface of PPS.

To address this need, OKUNO has developed a new process called the "TOP EP PROCESS," which enables the plating of electromagnetic wave shielding on PPS. This innovative technology takes advantage of the unique properties of PPS, delivering both an attractive plated finish and excellent shielding performance for product development.

Product features, specifications

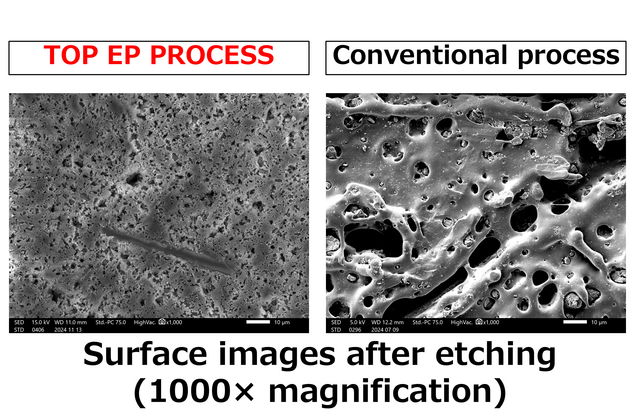

TOP EP PROCESS is a wet process used to form a thin metal film on PPS. This process can be easily integrated into standard production lines. It does not use environmentally harmful substances such as chromic acid, permanganate, or fluorides. Compared to conventional nitric acid-hydrofluoric acid etching methods, it provides a superior plated appearance and excellent adhesion.