Acid copper plating additive for through-hole filling on glass core substrates

TOP LUCINA GCS series

Currently, bismaleimide triazine (BT) resin laminated boards made of resin-based materials are used in the core of semiconductor package substrates.

Next-generation packages used in generative AI and data centers employ chiplet technology and multichip stacking to achieve higher chip integration and density, resulting in larger package sizes.

However, as package sizes increase, resin-based substrates warp and ripple, which significantly compromises reliability. Therefore, glass is gaining attention as an alternative material to ensure flatness.

Glass has many desirable properties, including flatness, stability of physical characteristics at high temperatures, a thermal expansion coefficient similar to silicon's, minimal distortion, and high rigidity.

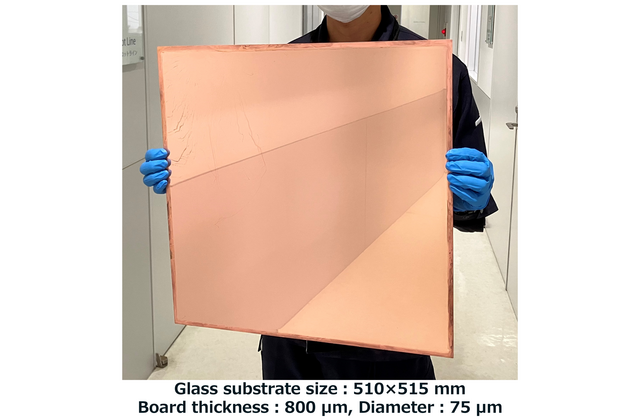

Using glass as the cores allow for large-size packages. However, combining glass's rigidity with miniaturization increases the aspect ratio of through-holes. Consequently, there is a demand for new technologies that can fully fill these high-aspect-ratio through-holes with plating rather than conformal plating.

Our company has recently developed a new series of copper electroplating additives for fully filling through-holes for glass core substrates. This new series is named "TOP LUCINA GCS" series.

Product features, specifications

・Best for plating on dimensionally stable glass core substrates

・A combination of PR pulse and direct current electrolysis using newly developed copper electroplating additives achieves void-free, fast through-hole filling.

・Can use for high-aspect-ratio through-holes