Featured

Environmentally friendly additive for hard anodizing of aluminum

TOP HARDNER AL

Normally, a hard anodic oxide film is obtained by lowering the temperature of the electrolyte, and it is used in automotive and aircraft parts and other applications where not only corrosion resistance but wear resistance and strength are required.

On the other hand, to obtain a hard anodic oxide film, a high voltage is required and the heat generated during electrolysis must be constantly cooled. Therefore, compared to general anodizing, this process requires a considerable amount of electrical energy to operate.

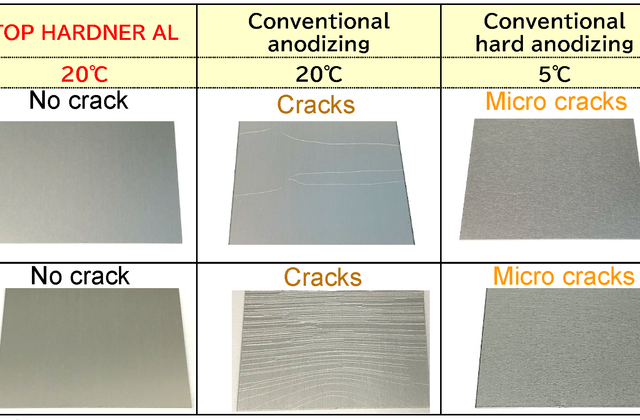

In response, we have developed a new environmentally friendly additive for aluminum hard anodizing, TOP HARDNER AL, which produces hard anodic oxide films with Hv400 or higher and good heat cracking resistance even at a bath temperature of 20°C.

Product features, specifications

Our new additive for aluminum hard anodizing, TOP HARDNER AL, increases the hardness of the film at the same temperature treatment compared to general anodizing by making the pore walls thicker and suppressing the dissolution of micropores formed in the film.

This makes it possible to obtain a hard anodic oxide film of Hv400 or higher even at a bath temperature of 20°C, and contributes to the realization of an environmentally friendly society by reducing the amount of electricity required for cooling.

In addition, the treated film has a low moisture content and exhibits high heat cracking resistance above 200°C due to the suppression of film shrinkage caused by heat treatment.

Environmentally friendly additive for hard anodizing of aluminum

We have developed a new environmentally friendly additive for aluminum hard anodizing, TOP HARDNER AL, which produces hard anodic oxide films with Hv400 or higher and good heat cracking resistance even at a bath temperature of 20°C.