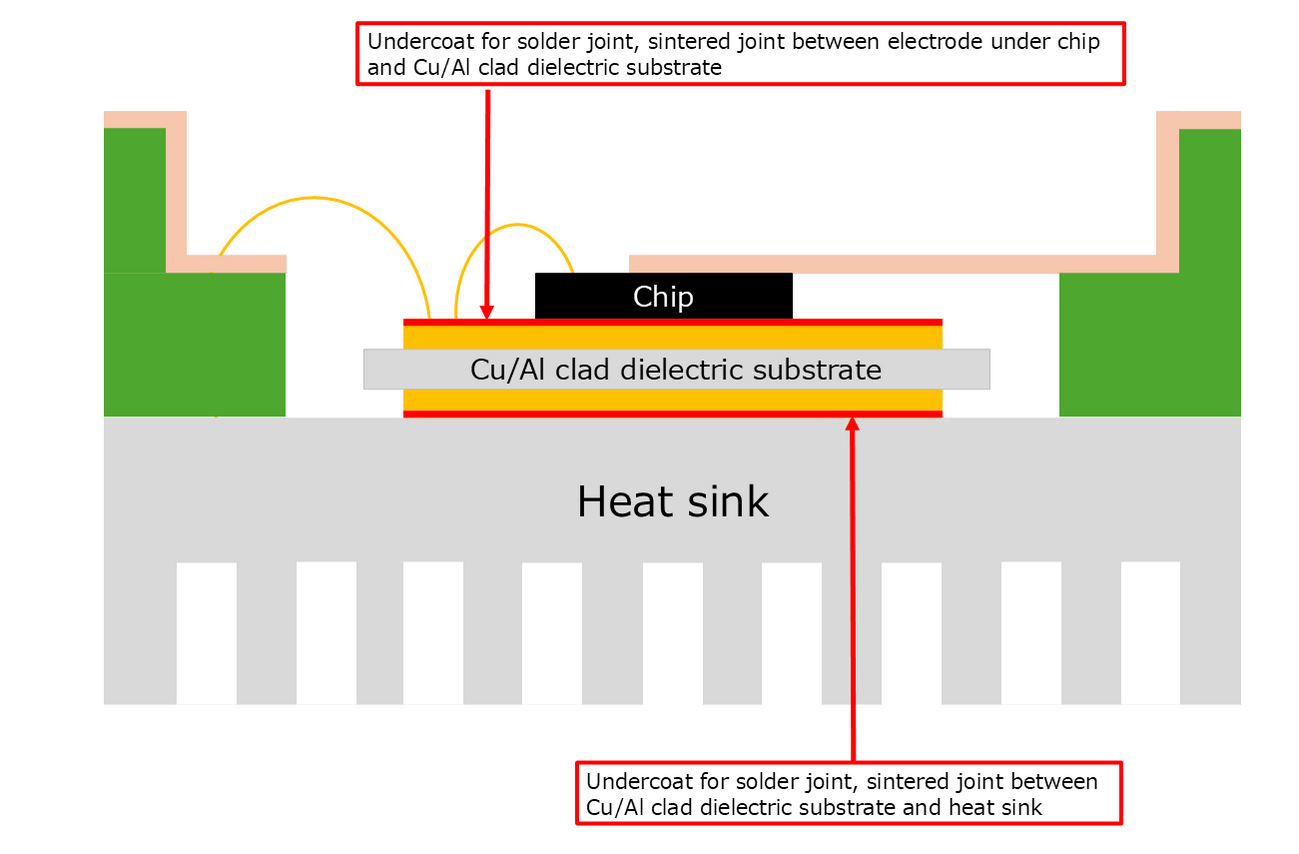

Application examples for power semiconductor devices

TOTAL PROCESS:

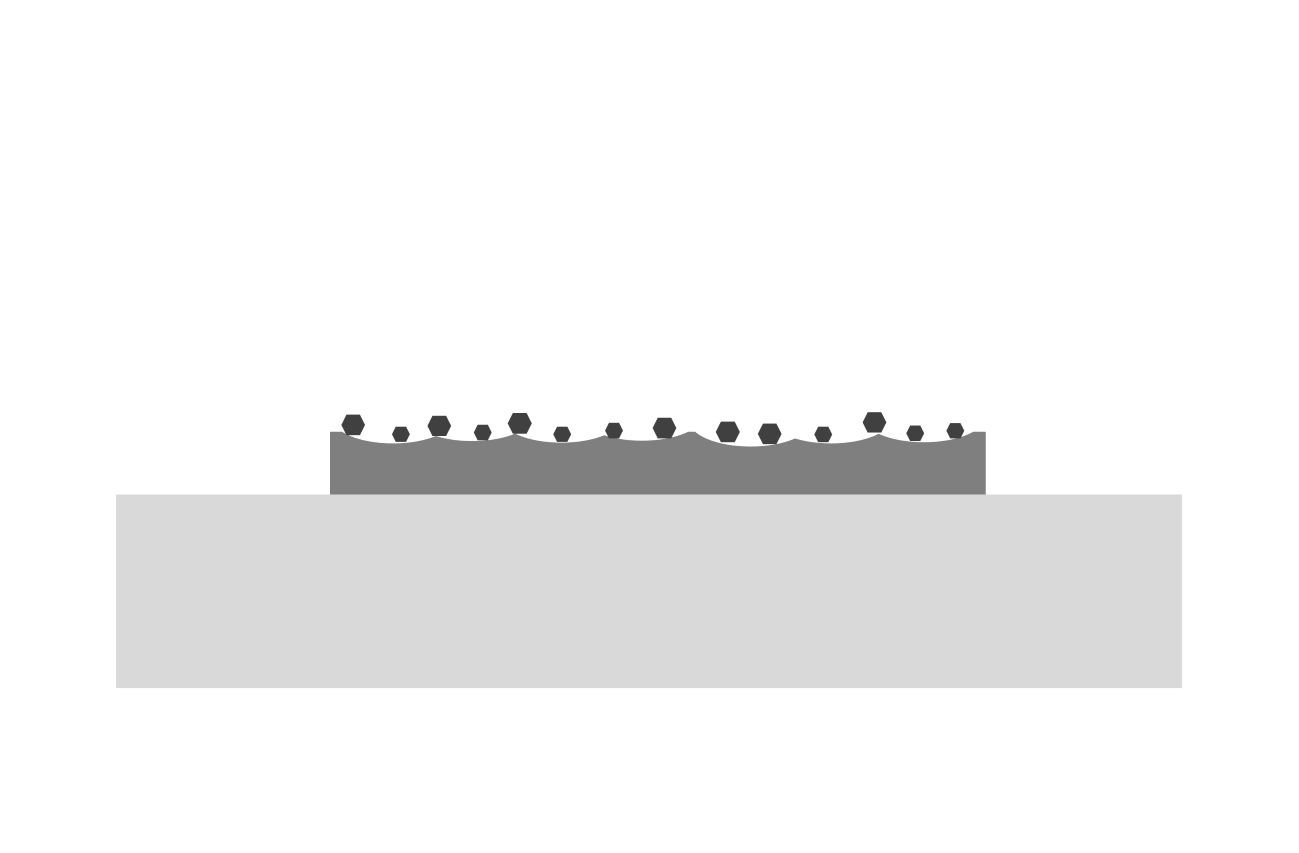

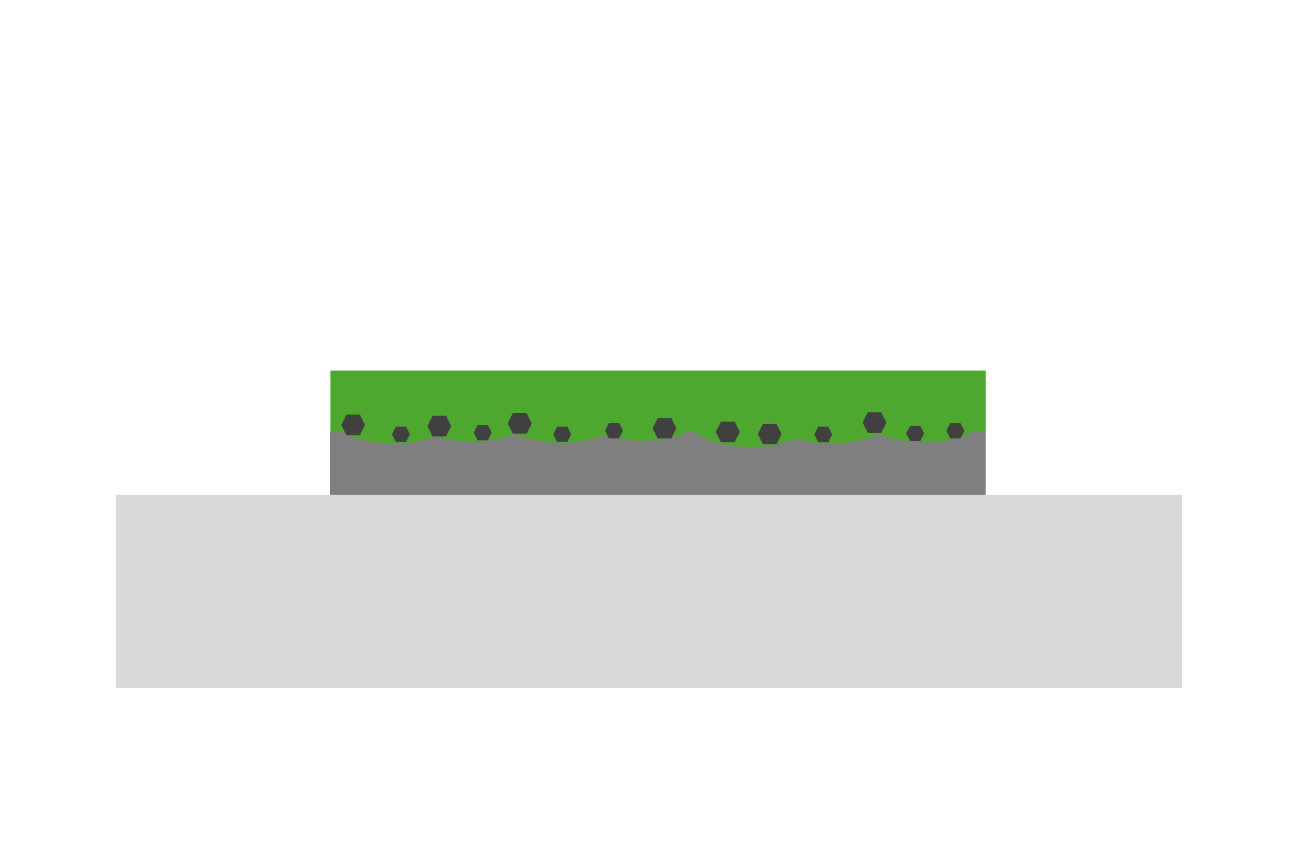

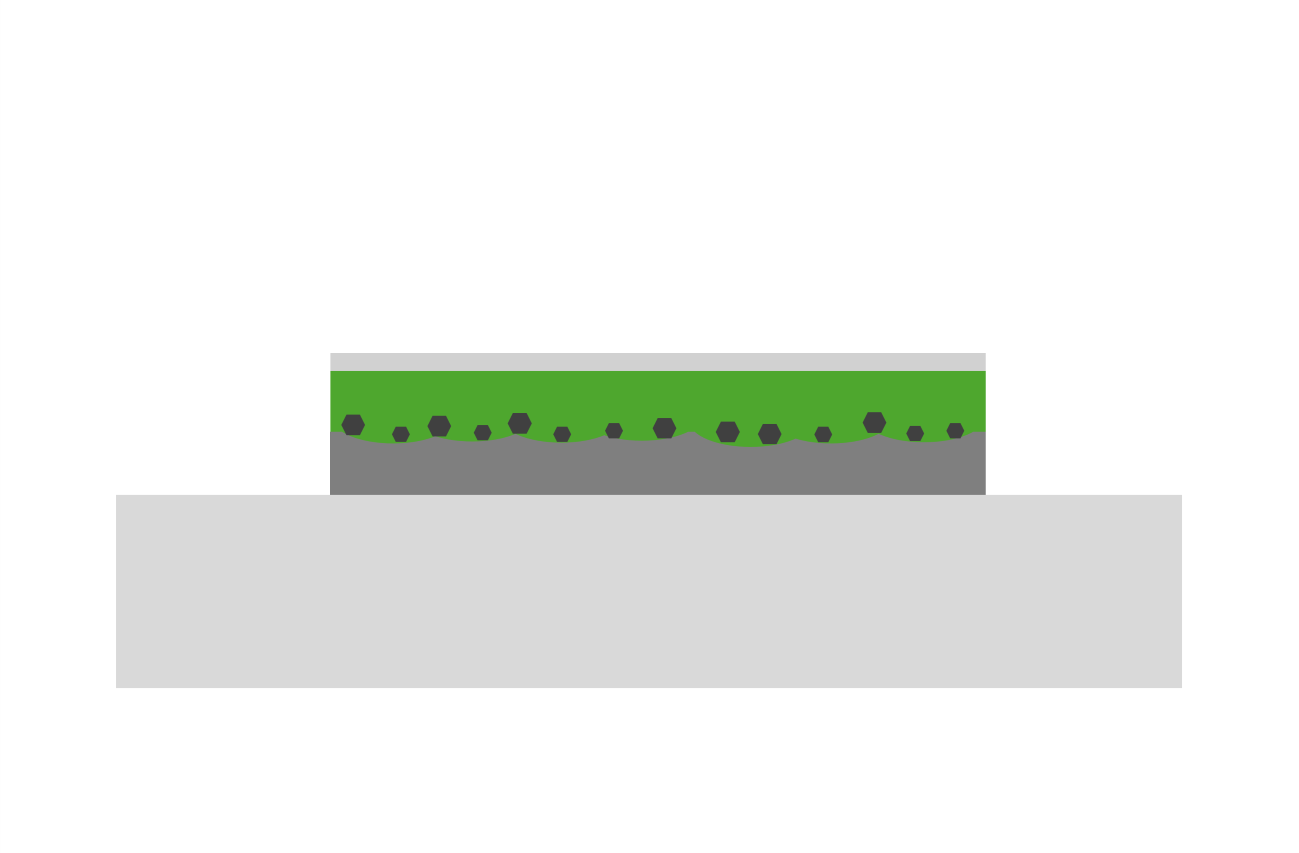

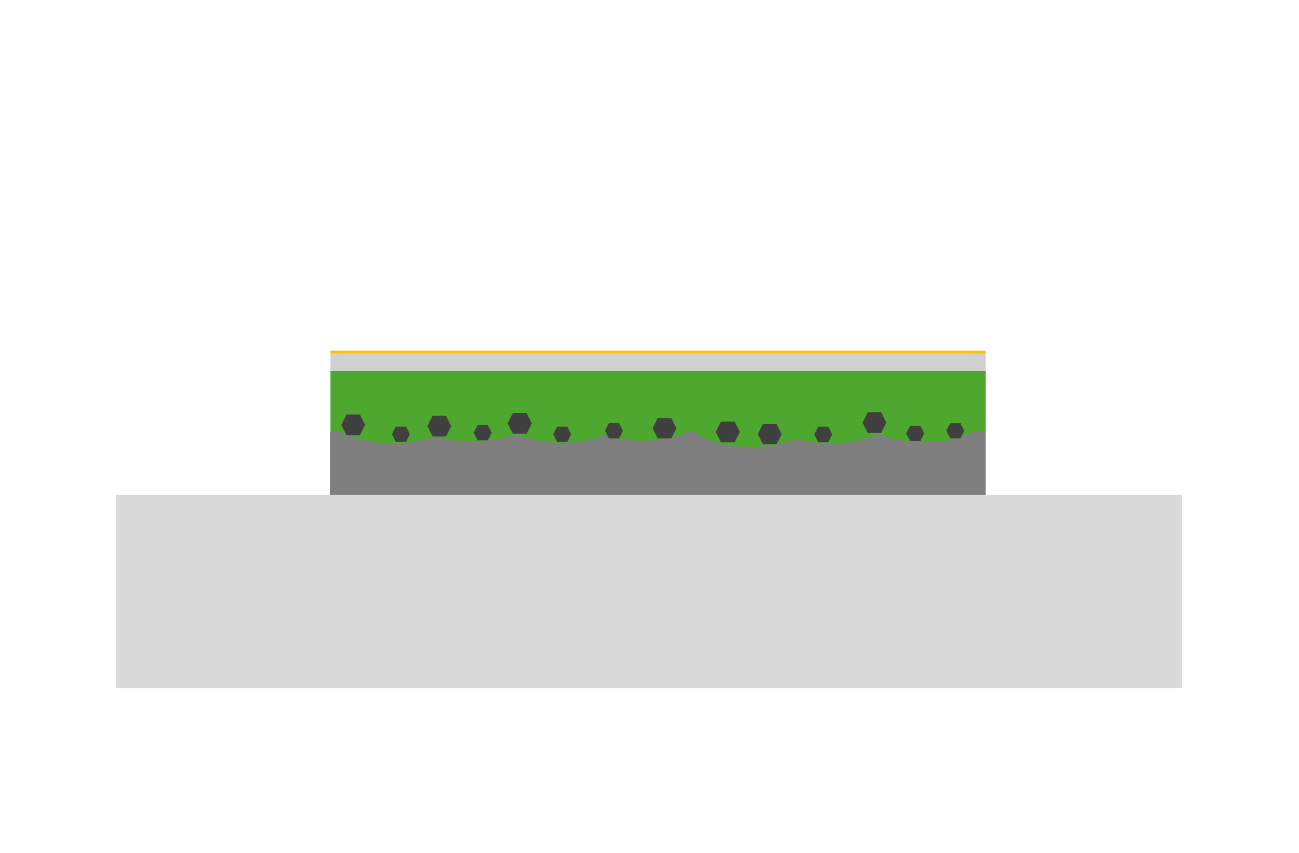

Electroless plating process for Direct Copper Bonding (DCB) dielectric ceramic substrates

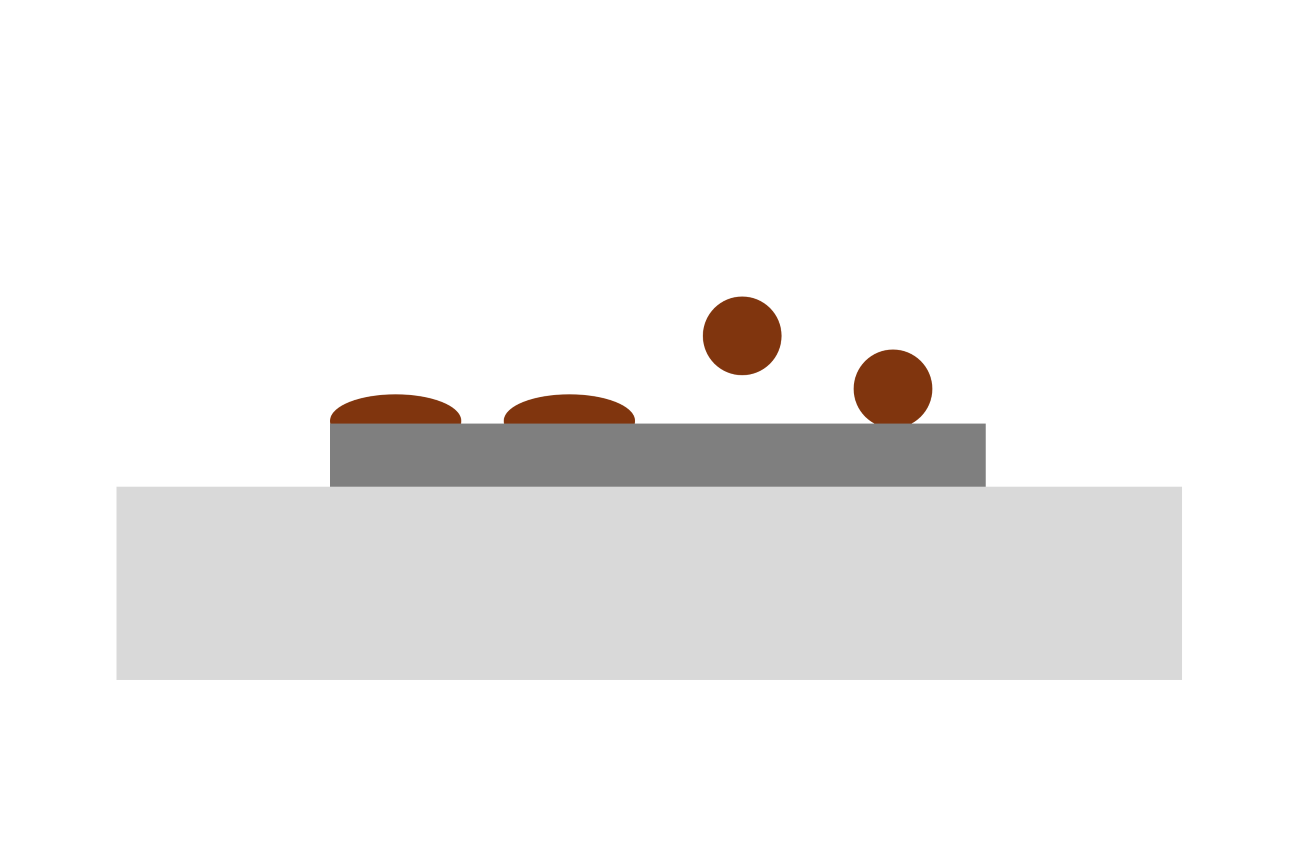

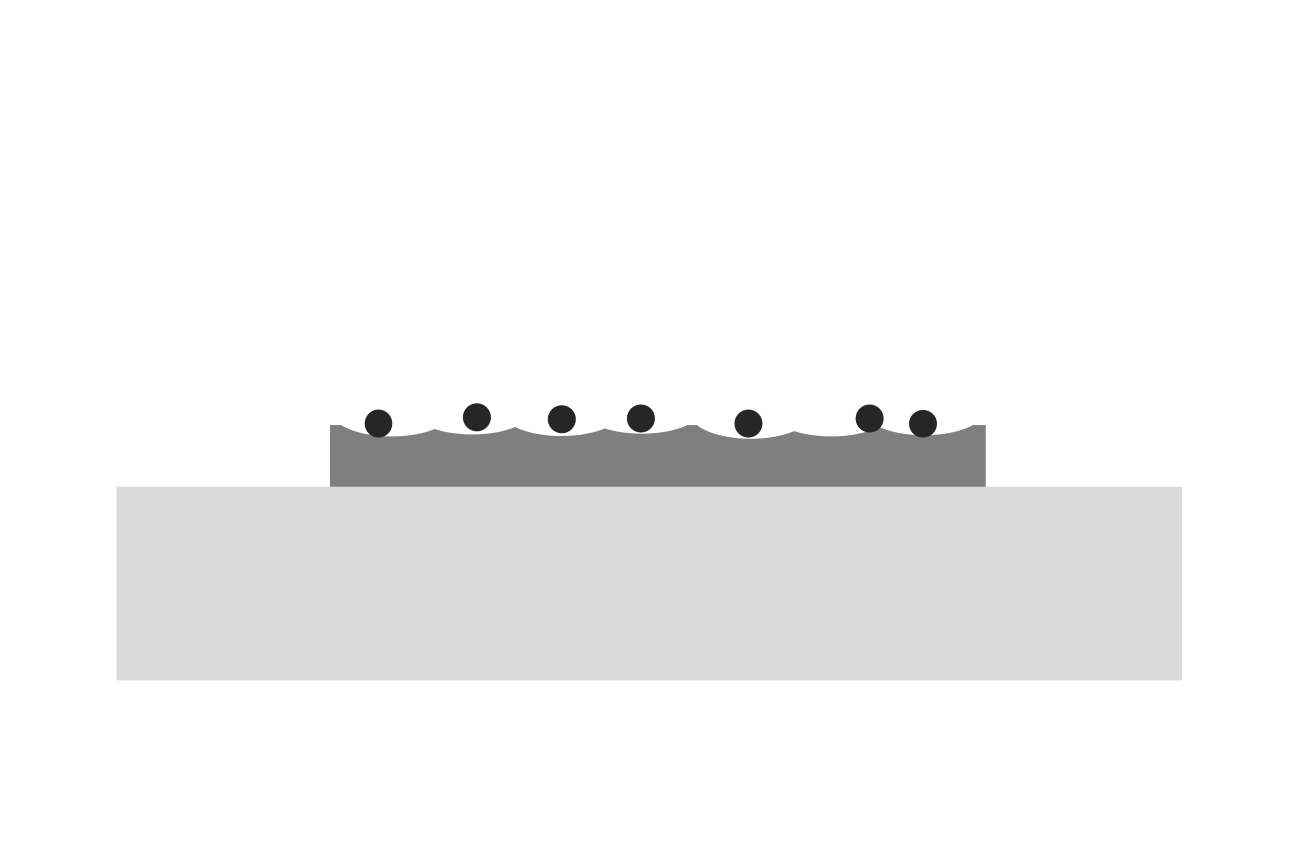

TOTAL PROCESS:

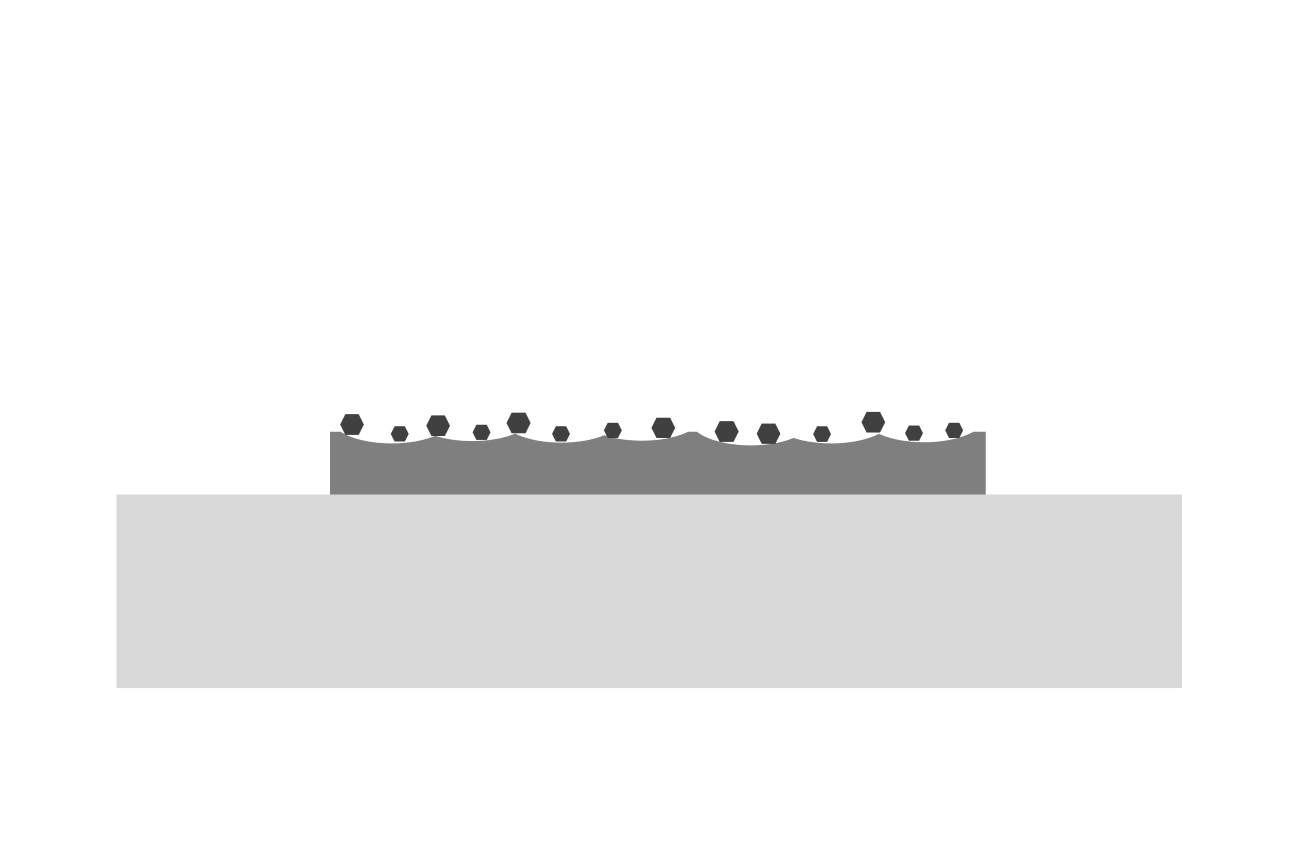

Electroless plating process applicable to UBM formation for aluminum electrodes on wafers