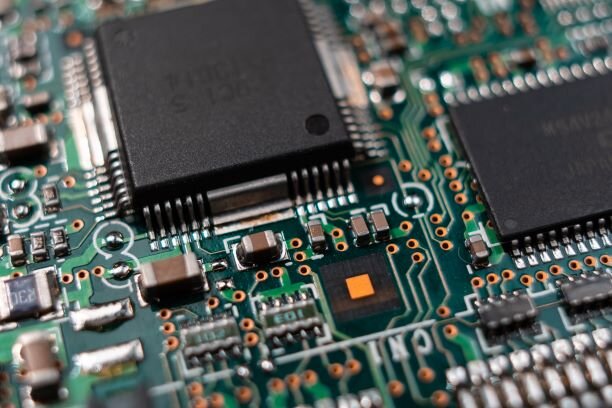

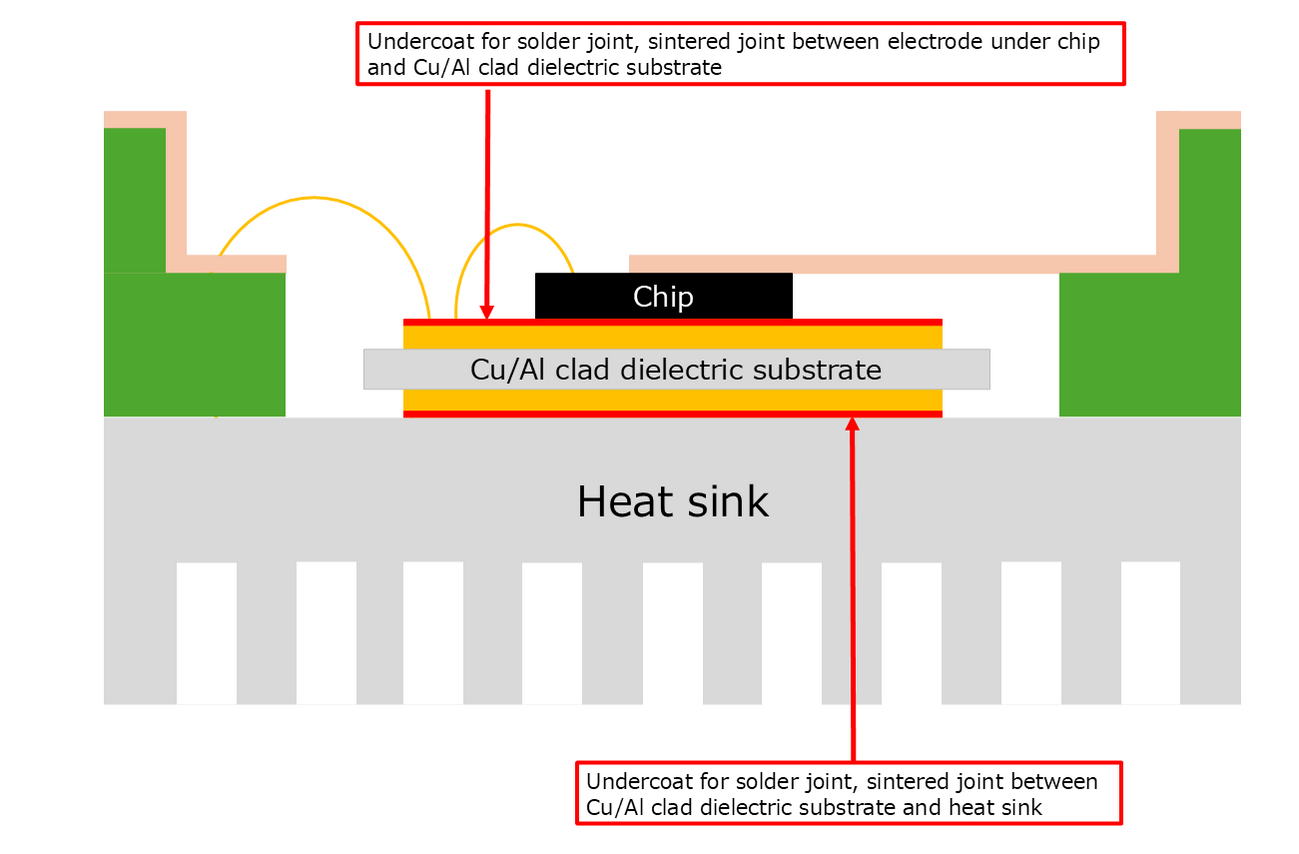

Application examples for power semiconductor devices

TOTAL PROCESS:

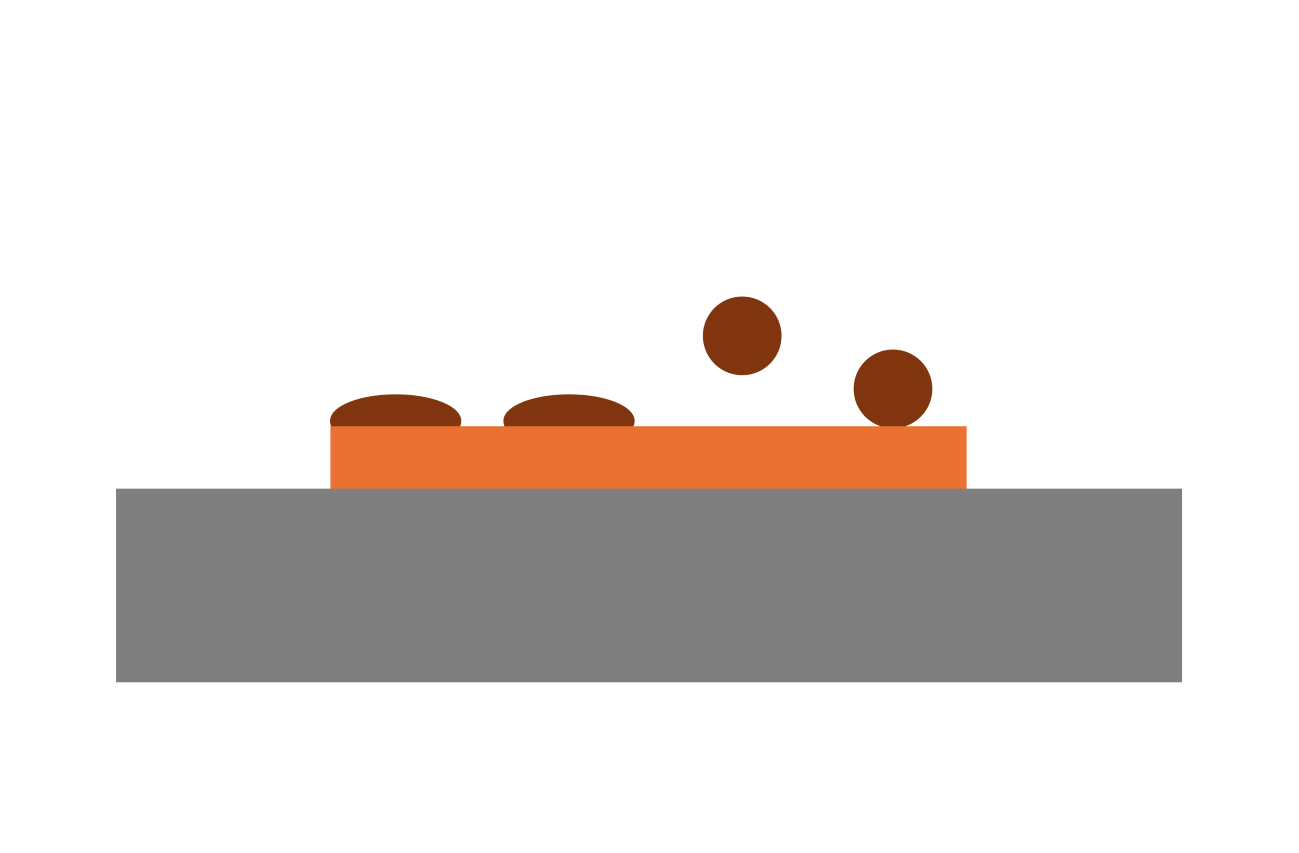

Electroless plating process for Aluminum Active Metal Brazed (AMB) dielectric ceramic substrates

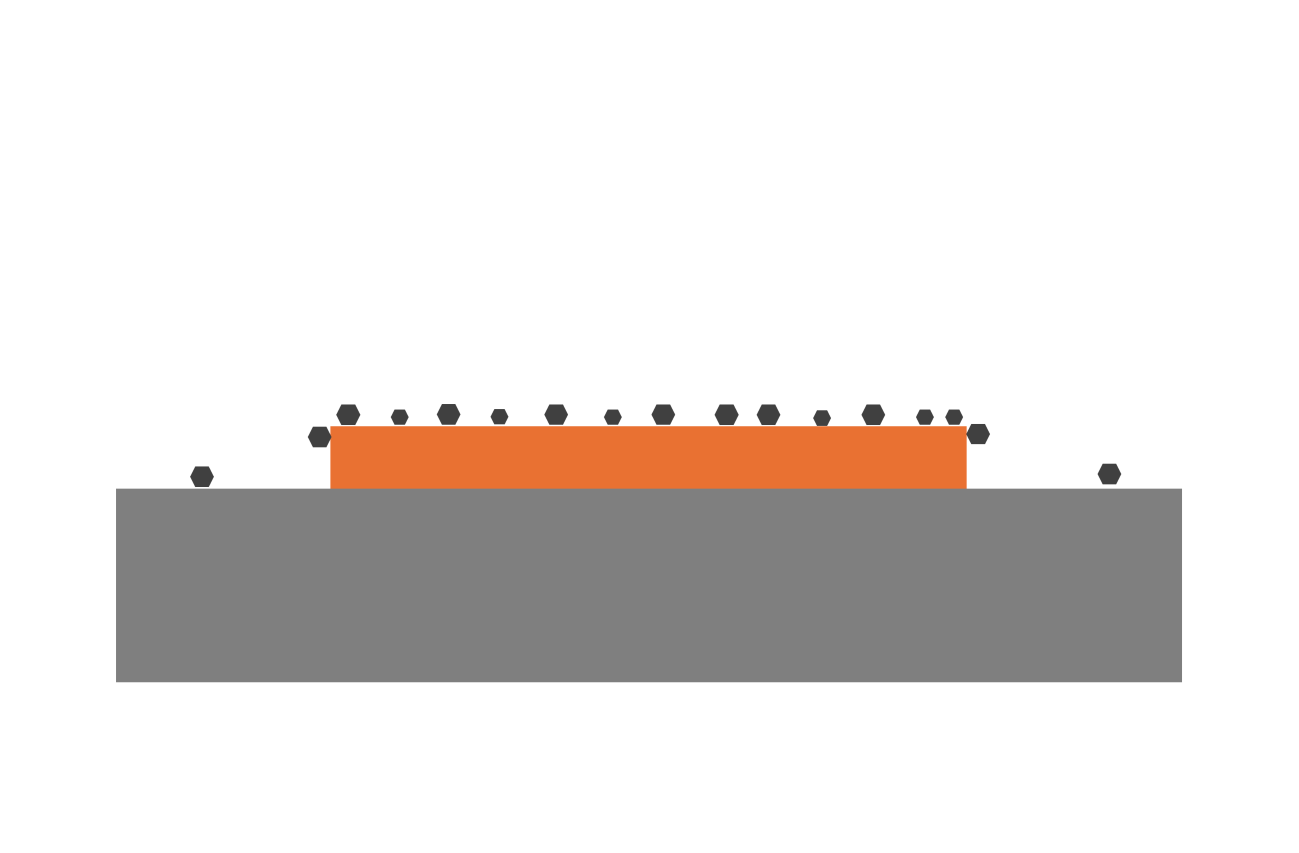

TOTAL PROCESS:

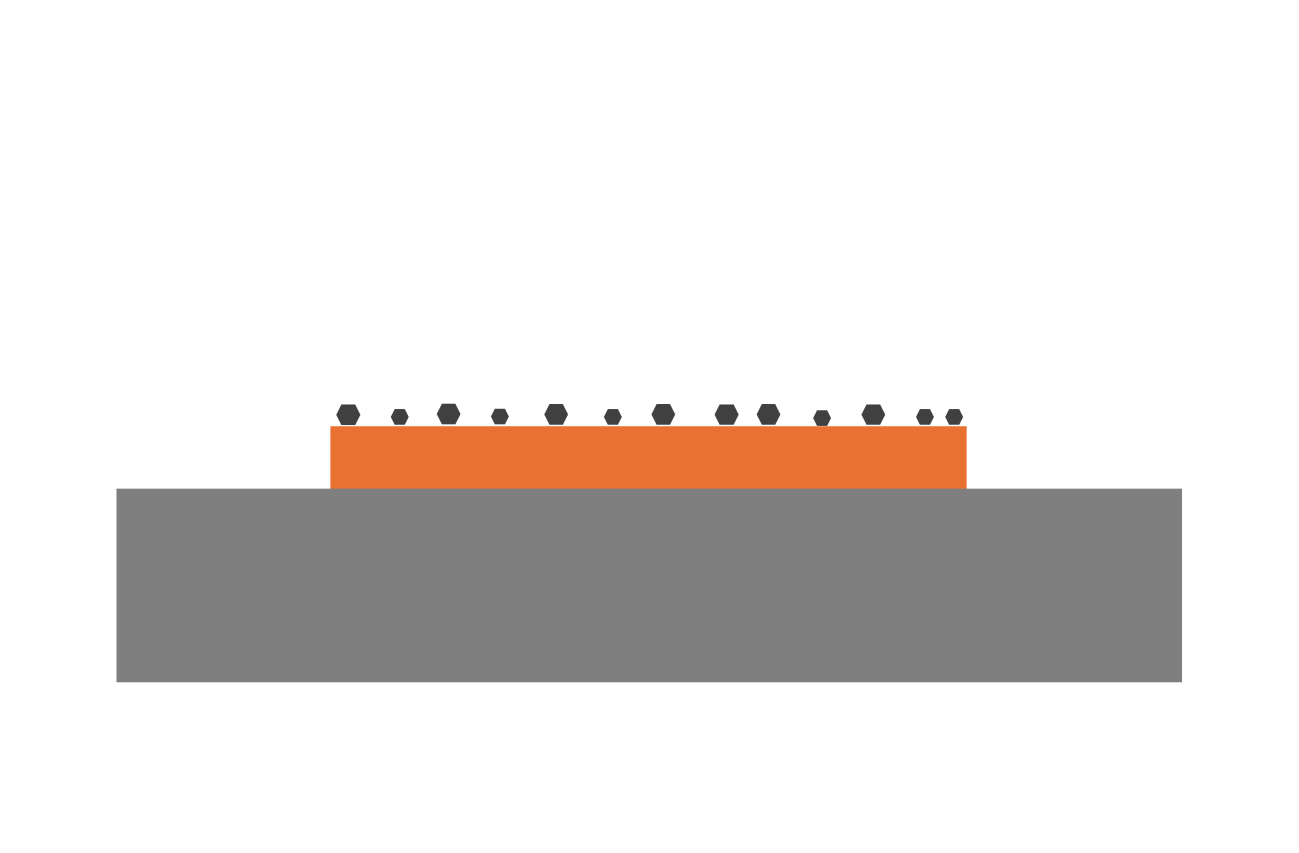

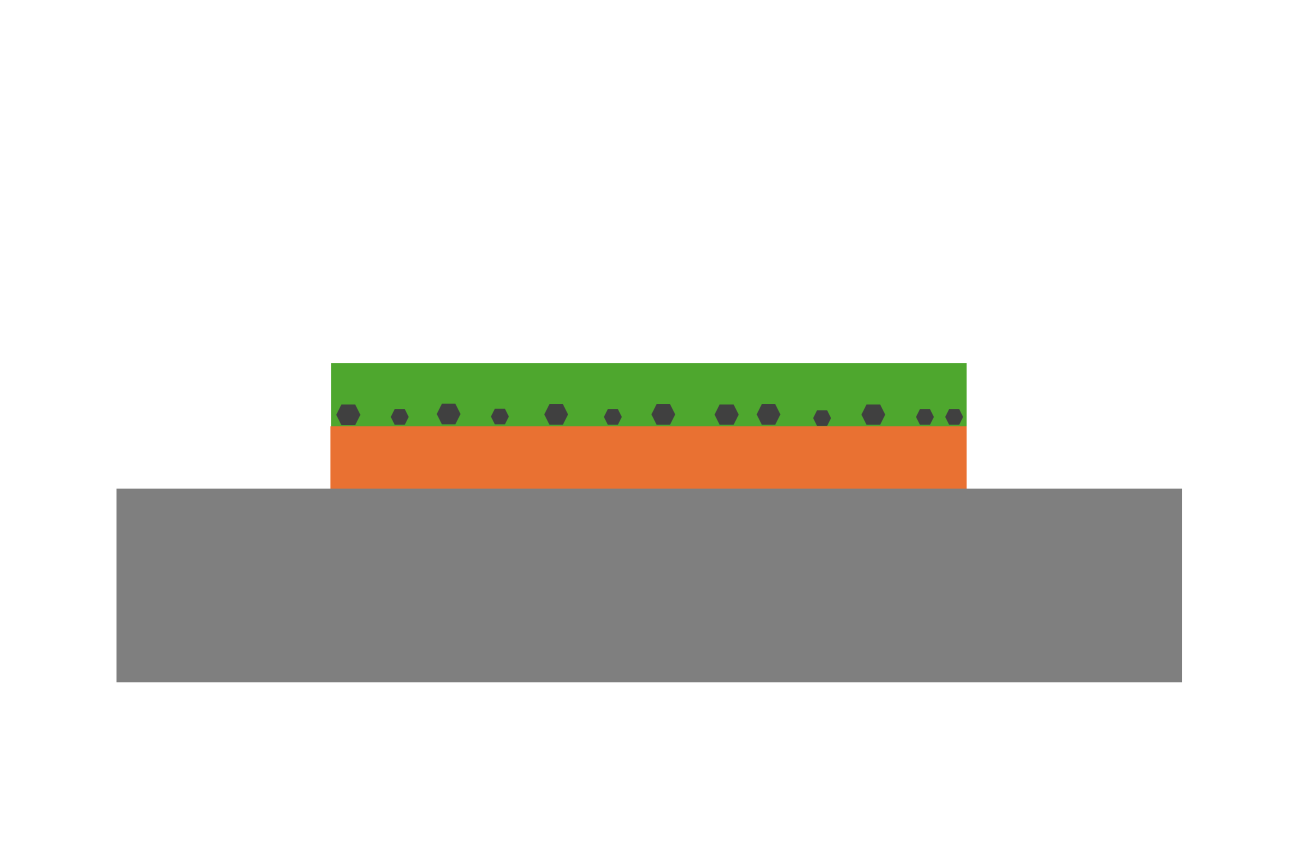

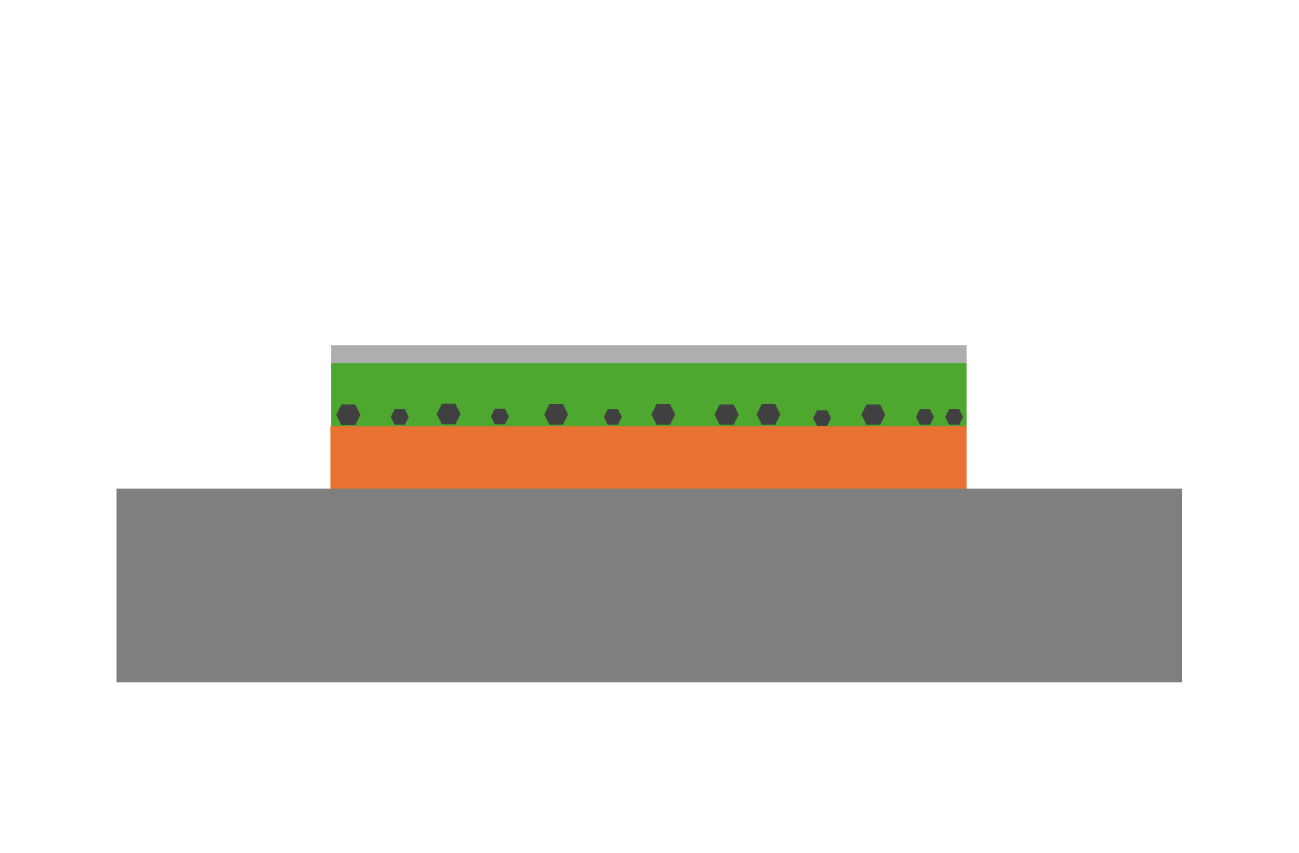

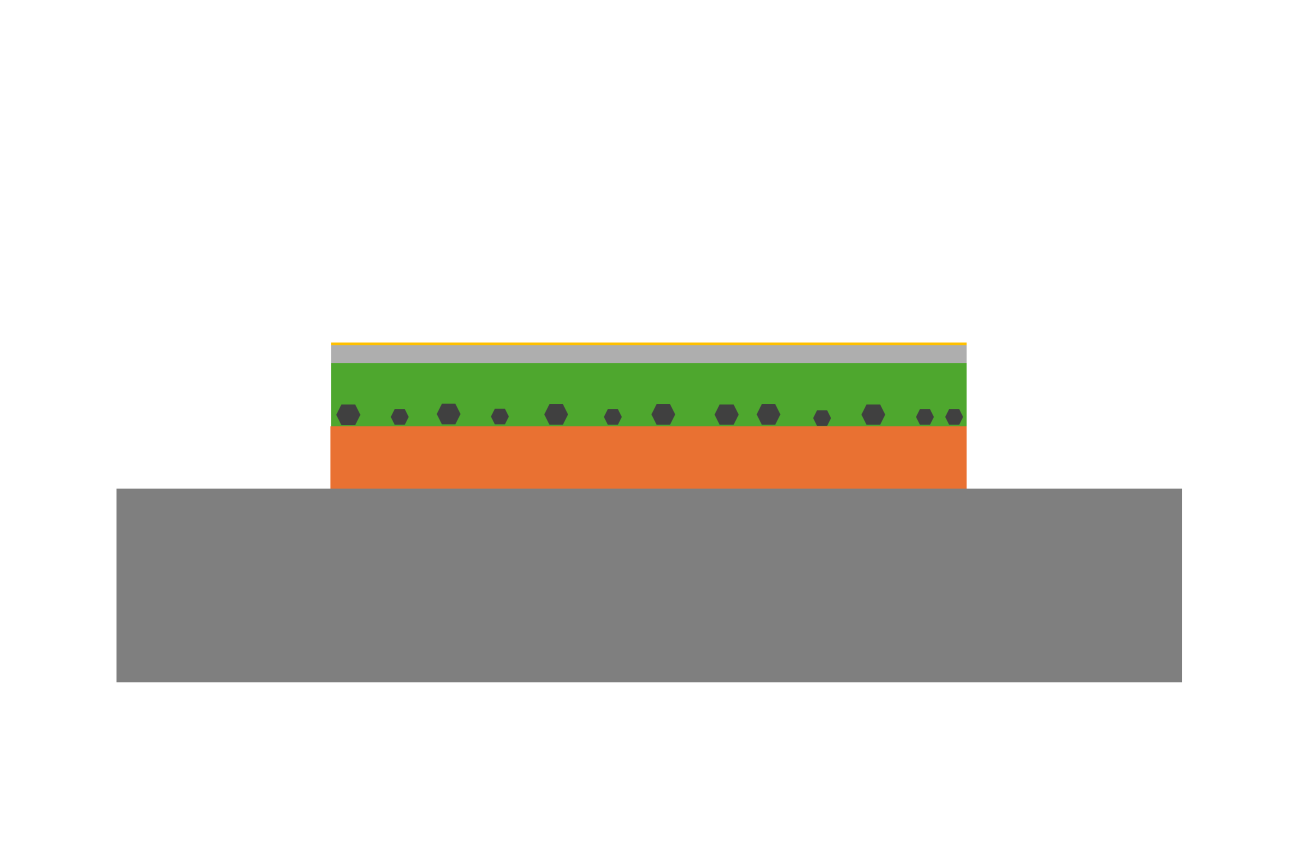

Electroless plating process applicable to UBM formation for aluminum electrodes on wafers