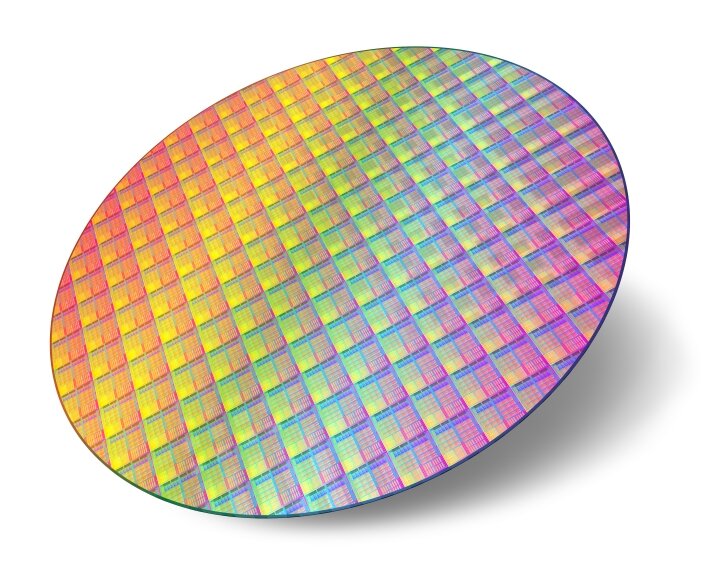

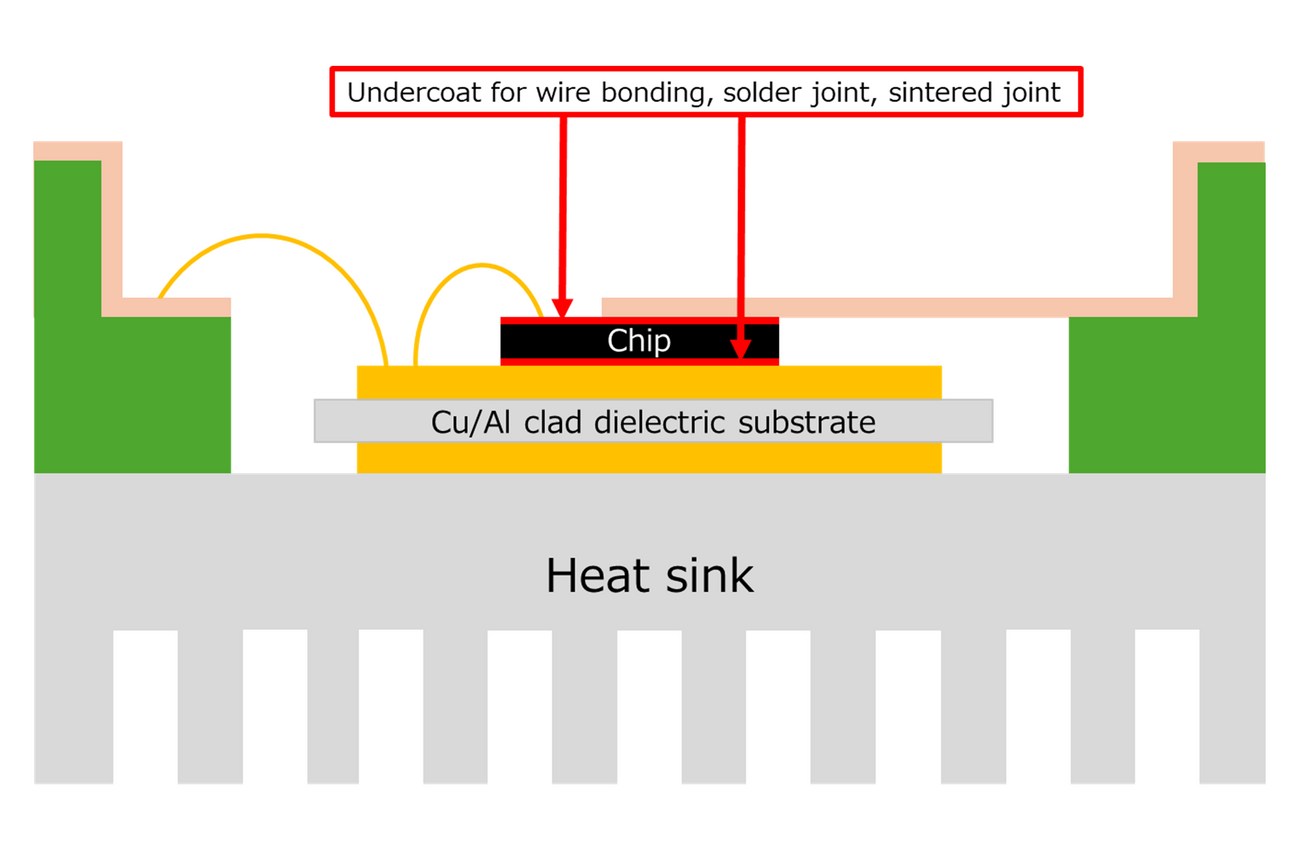

Application examples for power semiconductor devices

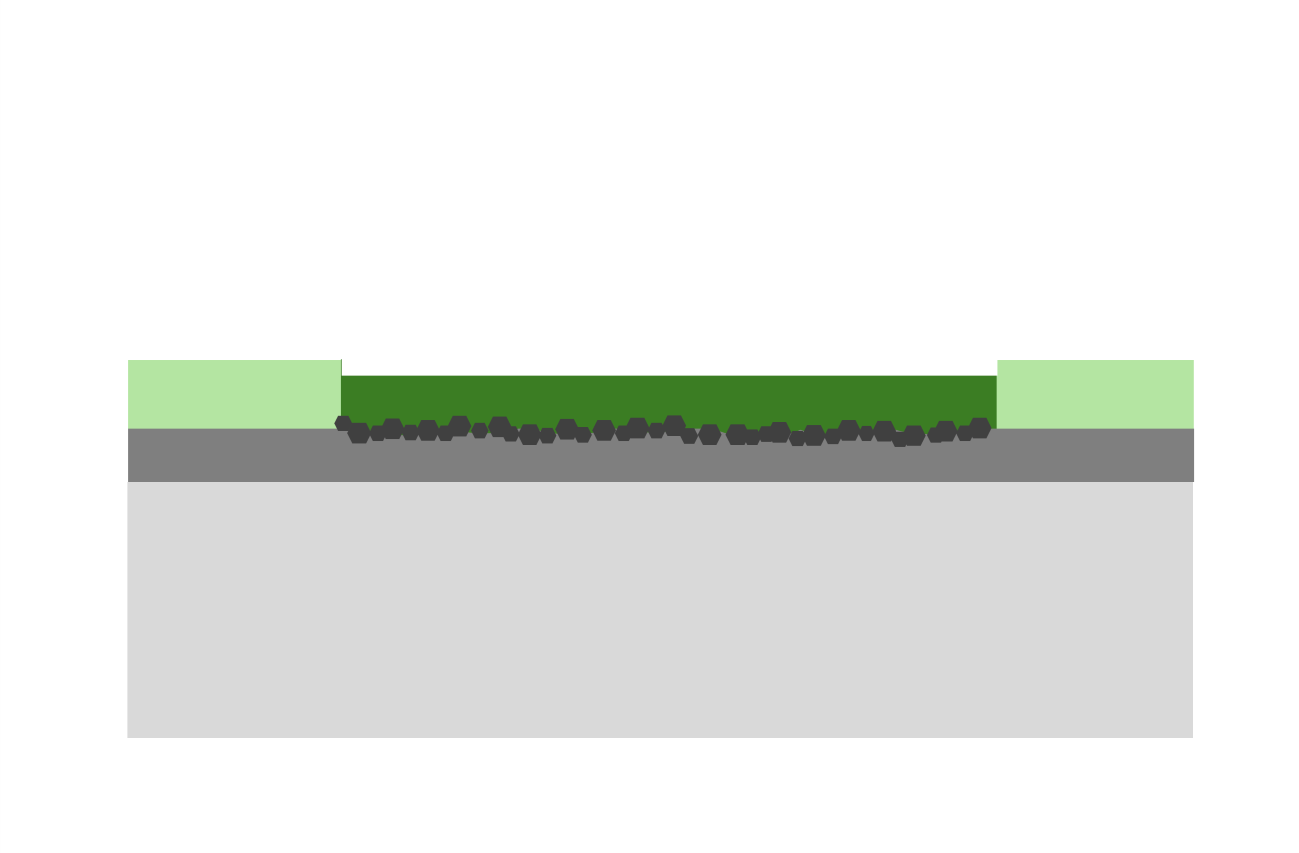

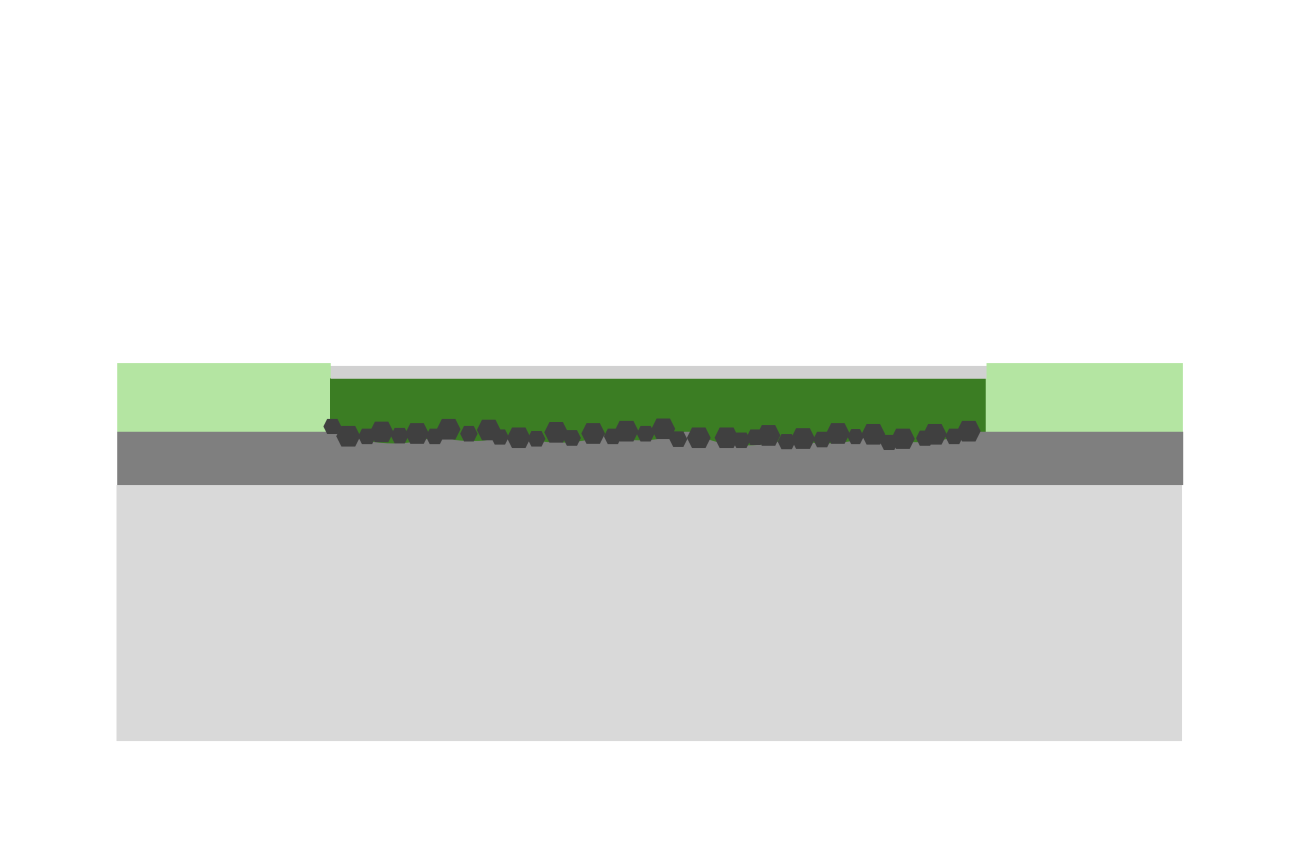

TOTAL PROCESS:

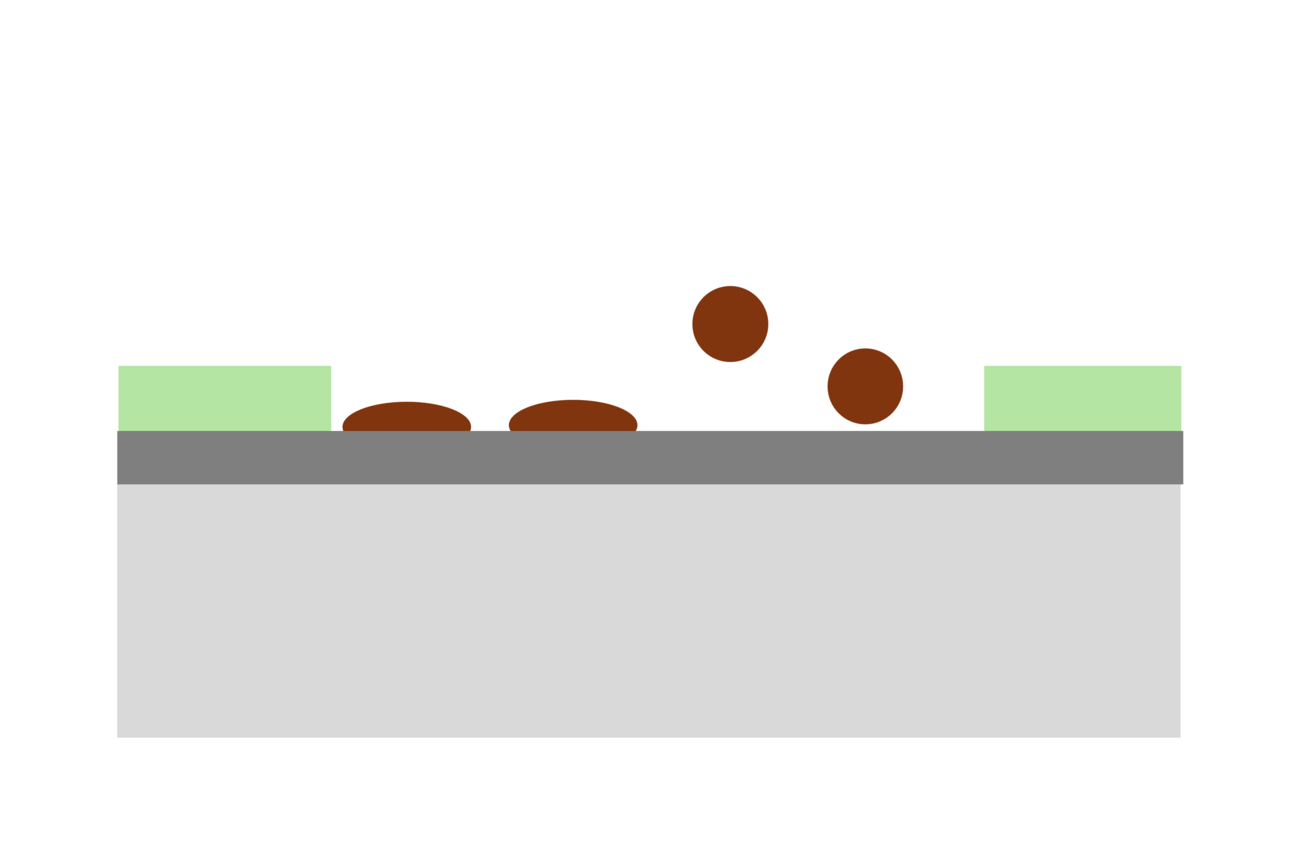

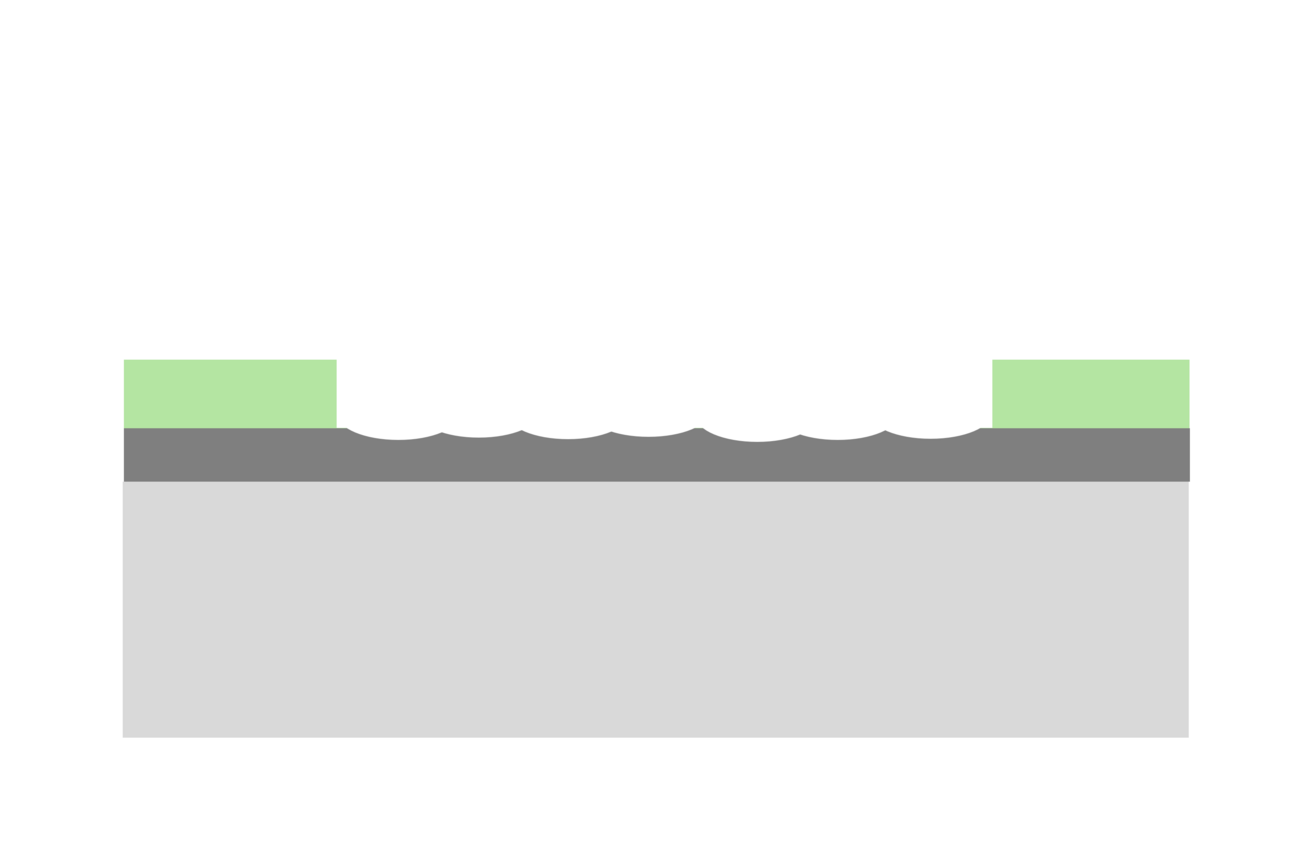

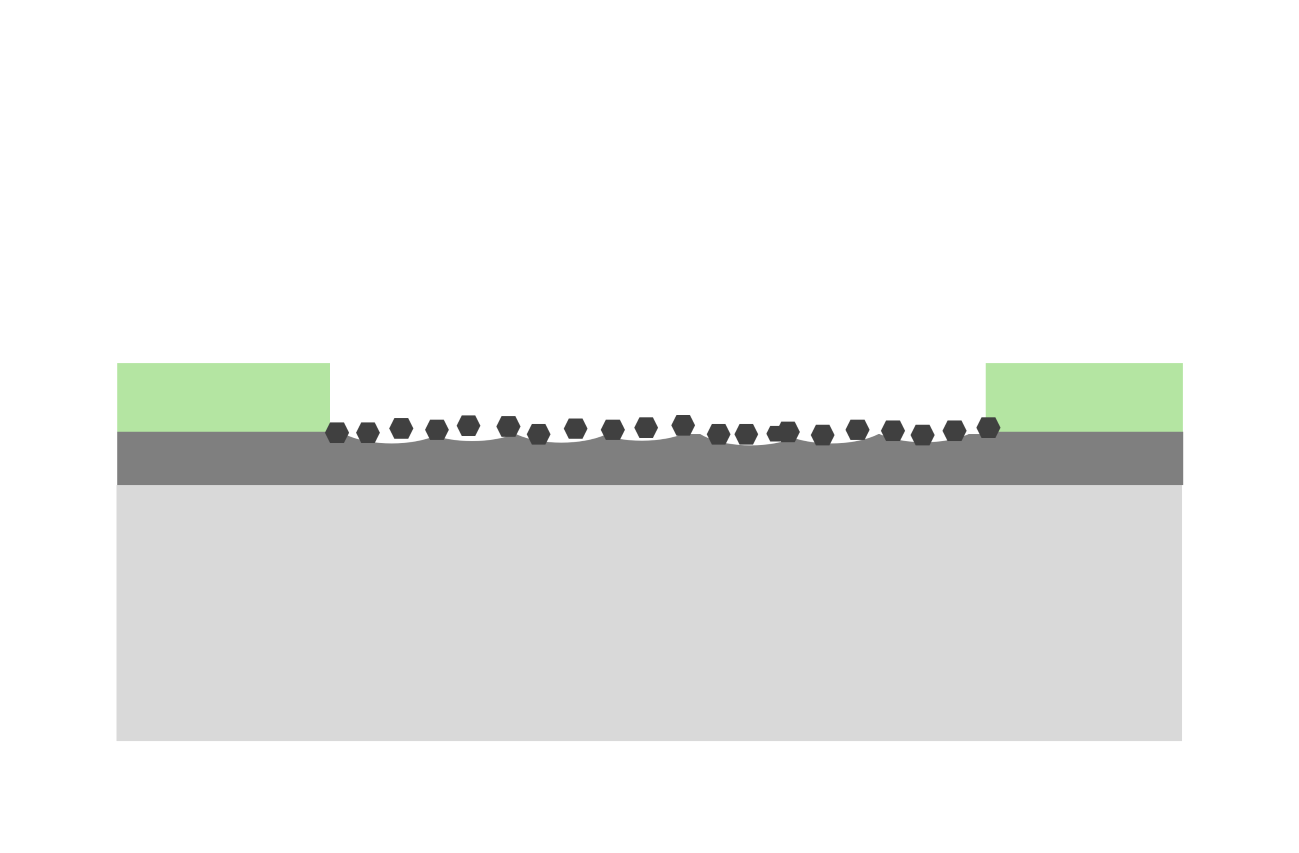

Electroless plating process for Direct Copper Bonding (DCB) dielectric ceramic substrates

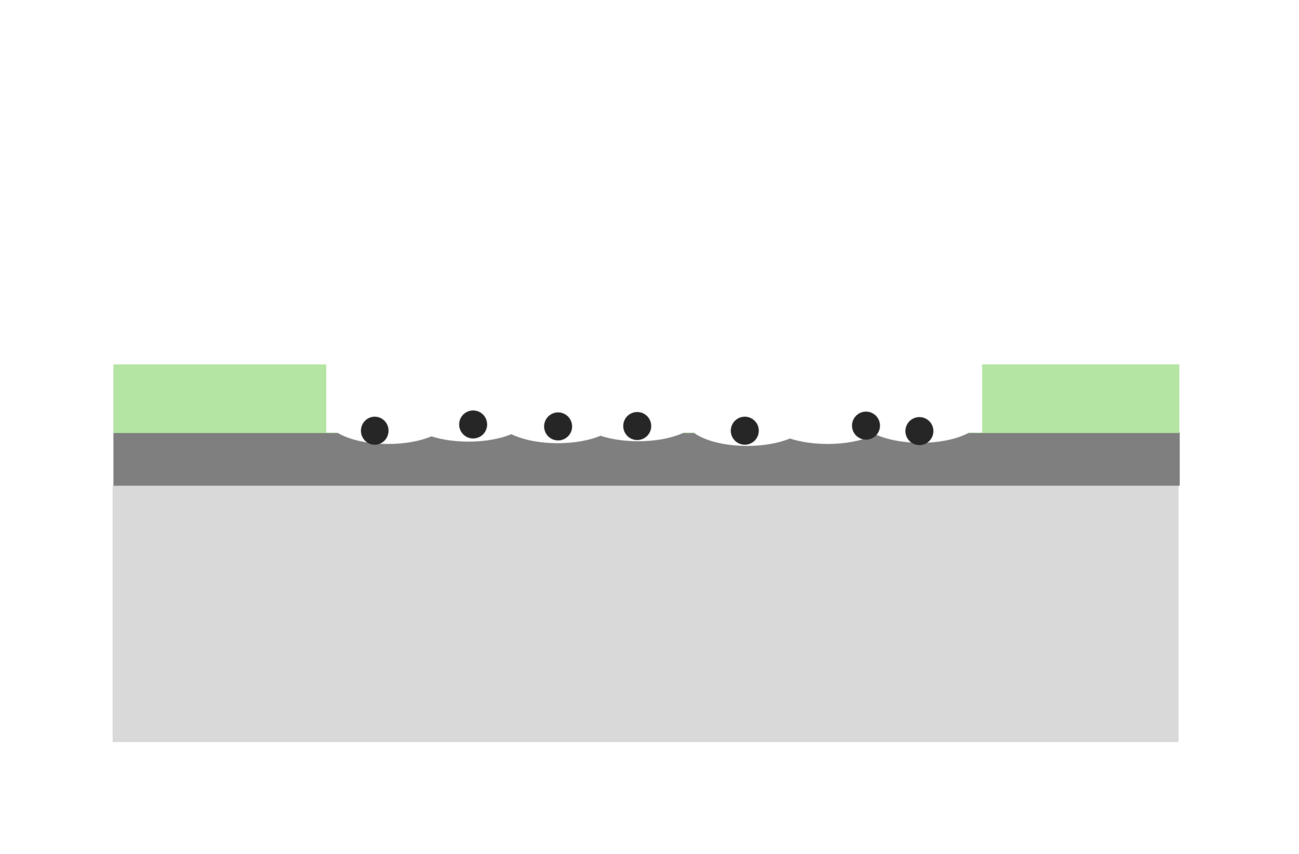

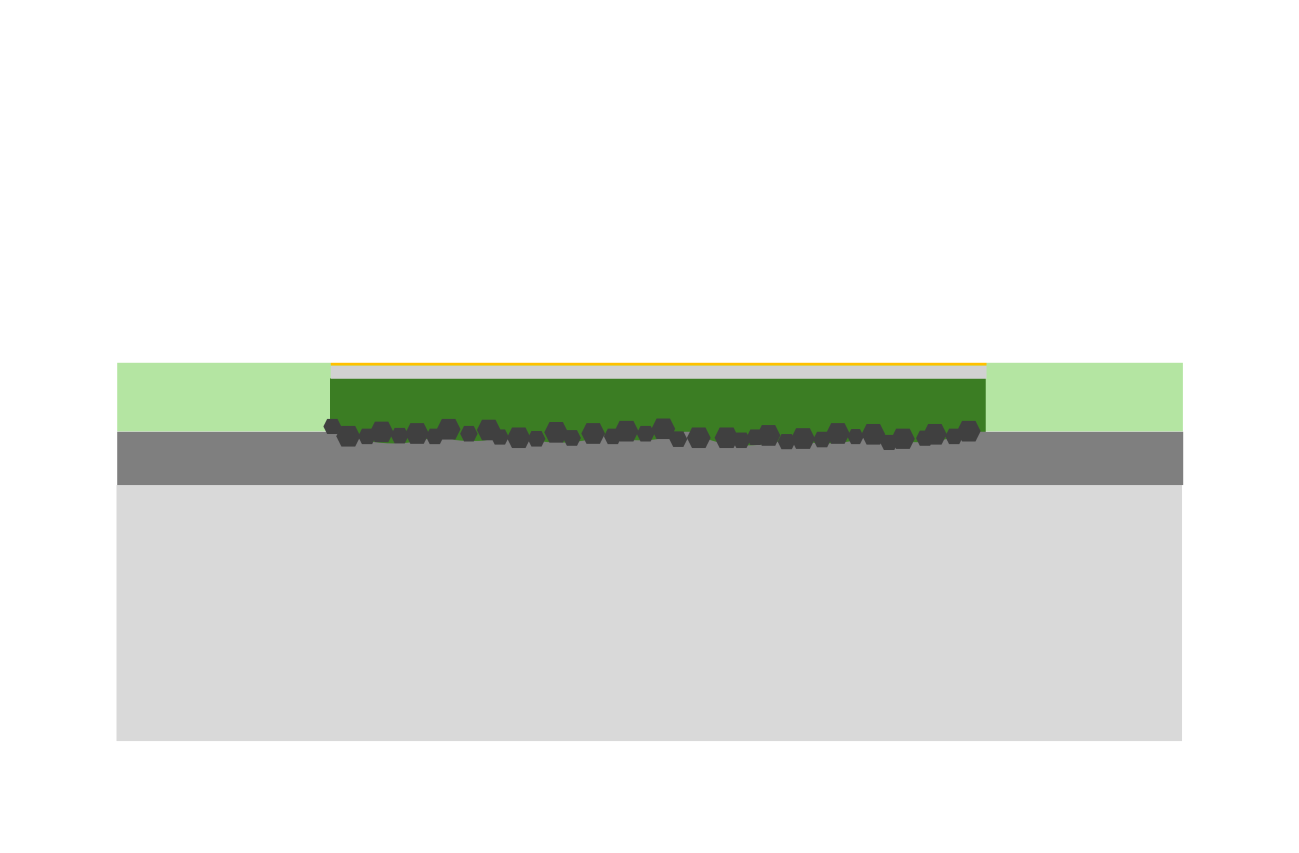

TOTAL PROCESS:

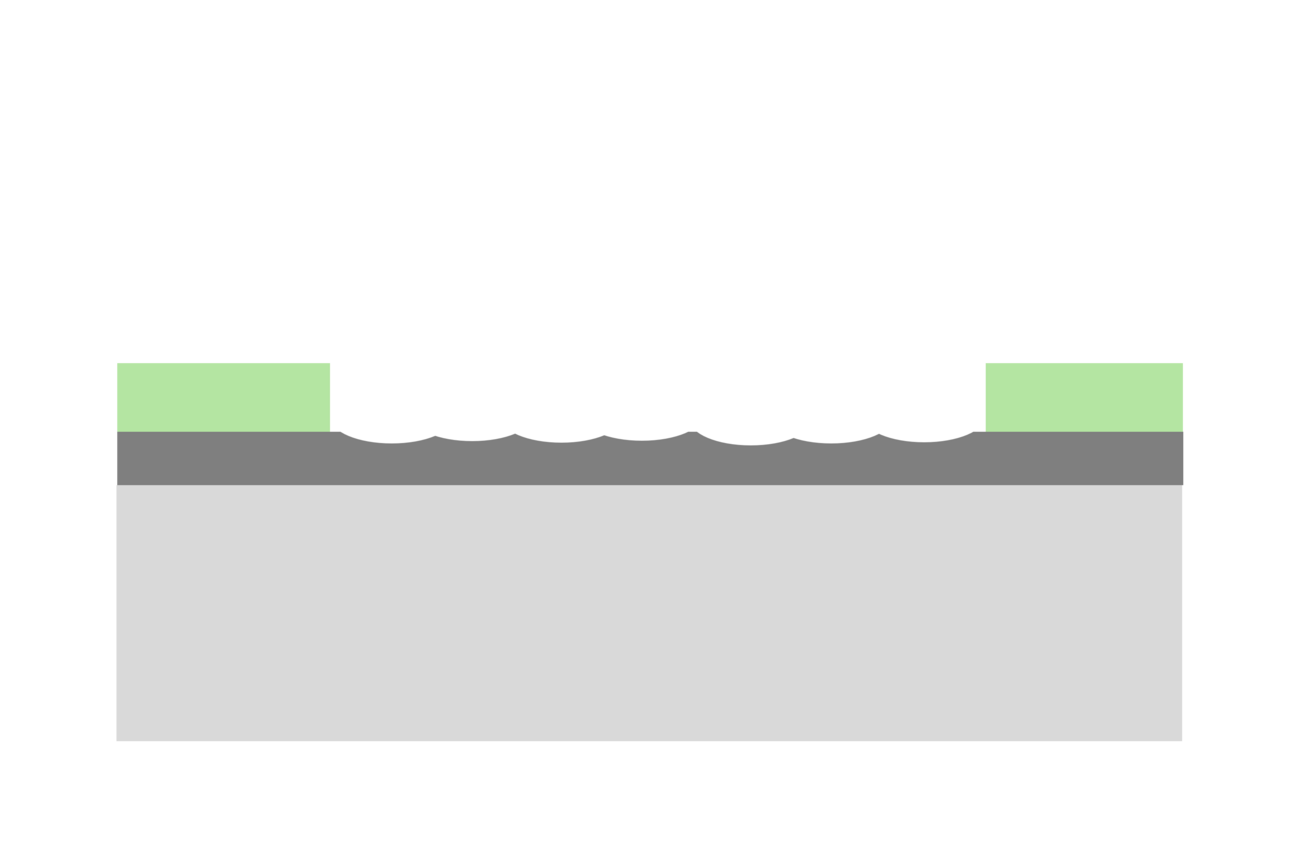

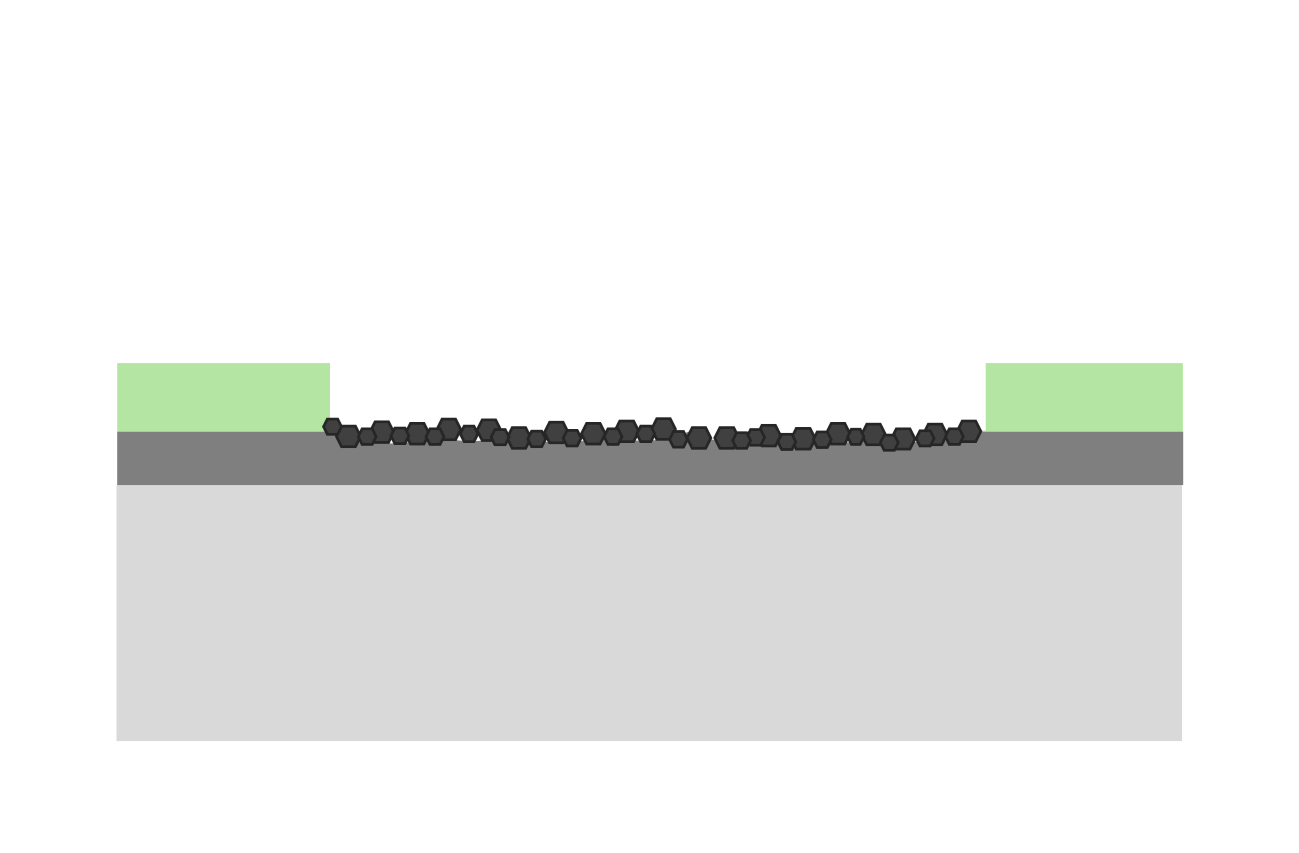

Electroless plating process for Aluminum Active Metal Brazed (AMB) dielectric ceramic substrates