Featured

Void-free final surface treatment using reduced cobalt catalyzing solution

ICP-COA PROCESS

![]()

Electronic components are mounted on printed circuit boards by wire bonding using gold, copper or aluminum wires, and by solder joint. Servers for ultra-high speed communications need to match with strong electric currents and large electric capacity. Thus, higher performance and advanced reliability are very important in the semiconductor packages and PWBs that are used with these electronic components.

We have succeeded to develop a catalyzing solution utilizing cobalt instead of palladium, and have launched void-free final surface treatment process to obtain finely uniform plating films. Our new process, ICP-COA PROCESS contributes to improve connection reliability of semiconductor packages and printed wiring boards.

Product features, specifications

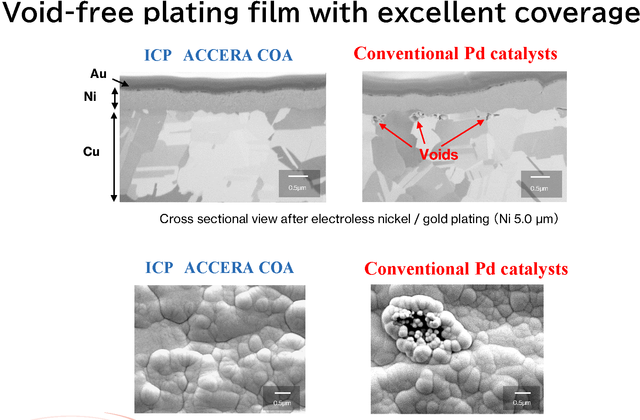

ICP-COA PROCESS is developed as a final surface treatment to plate on copper circuits using the catalyzer from reduced-type cobalt. Generally, catalyzers from palladium are used in conventional process. However, these palladium-based catalyzers occur substitution reaction, and voids can be found at the interfaces between copper circuits and plating films due to the excessive dissolution of copper circuits. On the other hand, our new process enables to form void-free and uniform plating films on copper circuits using the catalyzer based on reduced-type cobalt, and it can ensure further connection reliability in wire bonding and solder joint.

This process is widely applicable to electroless nickel/gold and electroless palladium/gold plating processes for semiconductor packages and printed circuit boards.

Void-free final surface treatment using reduced cobalt catalyzing solution

ICP-COA PROCESS is developed as a final surface treatment to plate on copper circuits using the catalyzer from reduced-type cobalt. This process is widely applicable to electroless nickel/gold and electroless palladium/gold plating processes for semiconductor packages and printed circuit boards.