Glass frit for

From product design to mass-production

Provide best solution promptly for higher performance

In order to realize the miniaturization of electronic devices and electronics components that are used for 5G communications, light, thin, short and small devices that have higher performance are strongly demanded. Also, we need to develop these devices quickly to keep up with high-speed IoT technology.

OKUNO is a leading provider for glass frit because we also have a long history as the supplier for plating chemicals. By the combination of glass and plating technology, we provide seamless solutions from the development of glass compositions to mass-production. Especially, we have helped to solve many problems before and after firing, sintering, coating and plating steps. To realize the miniaturization and to achieve higher performance in electronics components, we offer innovative products and professional technical service as a global leader from a surface finishing industry.

OKUNO's strength

-

01

Shorten process

from product development to mass-production*Find the best glass composition for your own purposes.

-

02

Deliver

quickly from small quantities*Glass specialists from lab tests to mass-production.

-

03

Open laboratory

to discover answers together*Can test at in-house laboratory. Promptly find the best solution together.

Process from electronics component design to mass-production

-

01

First meeting

Consulting to know required specification (Firing temperature, chemical/plating-chemical resistance)

-

02

Recommend the most suitable glass frit

Recommend the most suitable glass frit from rich experiences

-

03

Evaluation at our customer

-

04

Adjust product to fit mass-production line

-

05

Final evaluation

-

06

Make mass-production schedule

Can supply as glass frit, paste and slurry

-

07

Mass-production

Reschedule delivery time

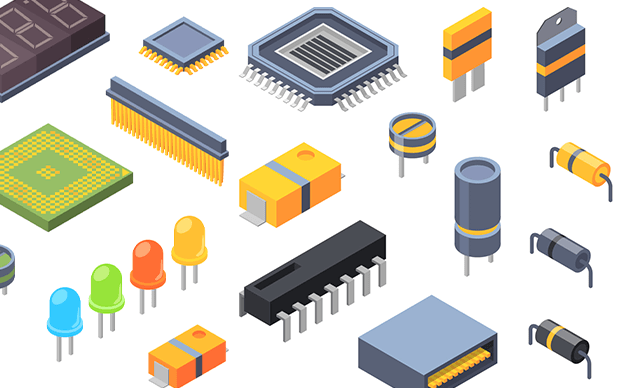

OKUNO's glass frit around you

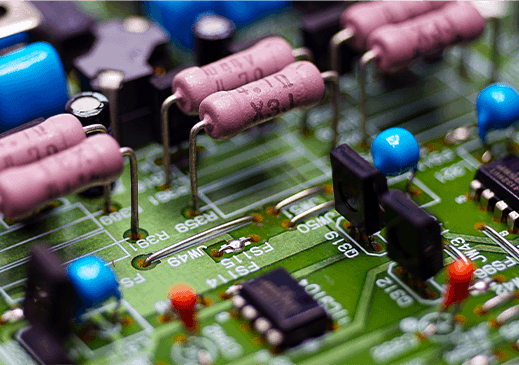

Resistor

- Sintering aid: Help the sintering of ceramic substrates at a low temperature

- Sintering aid: Work as a binder to bond resistor films and electrodes

- Overcoat glass : Protects resistor films and elements from outside

- Marking glass: Used to distinguish products

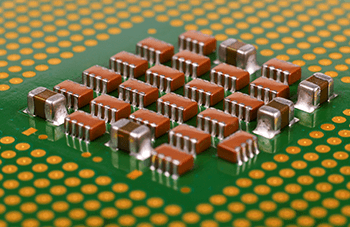

Capacitor

- Sintering aid: Work as a binder to bond dielectrics

- Sintering aid: Work as a binder to bond electrodes on ceramic substrates

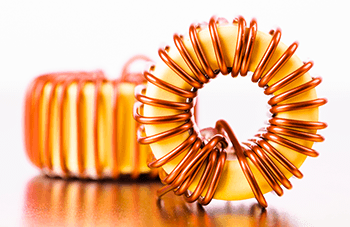

Inductor

- Overcoat glass: Protect elements from outside

LED

- Overcoat glass: Protect electrodes of LED mounted substrates

Solar cell, fuel cell, sensor, thermal head, etc.

(For insulating property and airtightness)

- Glass coating: Used as passivation film

Case

Case AAt the customer who uses the glass pastes of other company, voids occur in glass after firing and the insulating property is lowered.

[Cause]

Glass frit can't be printed on substrates directly because it is powder. Thus, organic vehicles (resin and solvents) are mixed with glass frit to make glass pastes, and the glass pastes are applied on substrates by screen printing. After the printing, the substrates are fired slowly to melt glass and to decompose the organic vehicles by heat. After firing, only glass remains on substrates since glass is an inorganic material. The organic vehicles are decomposed by heat and released into the air as carbon dioxide.

In the case, the voids occur in the melting reaction because:

① Carbon dioxide is not released completely and remains in glass after firing, or,

② The organic vehicles are not decomposed by heat completely, and remains as residues.

[Countermeasure]

We have developed the glass paste containing other resin in the organic vehicle. Since the resin can be decomposed easily at a lower temperature, the void occurrence can be solved.

Case BThe circuit patterns on LTCC substrates, which are formed by a silver paste, are plated. However, poor adhesion and low-plating speed is observed because a part of the glass components are dissolved into a plating solution from the printed patterns.

[Cause]

We conduct an in-house trial using the glass paste. We discover that the glass frit, which are contained in the silver paste as a sintering aid, doesn't have sufficient plating-chemical resistance. Thus, a part of the glass components are dissolved into the plating solution from the patterns.

[Countermeasure]

We change the amount of silicon, boron, and other oxides in the glass frit, and succeed to improve chemical resistance of the low-temperature melting glass frit without increasing the firing temperature. Furthermore, we develop a new plating process (NNP PROCESS) exclusive for LTCC substrates since LTCC substrates show a weak chemical resistance.