SEARCH PRODUCT

- Pick up:

-

OKUNO’s products in Metal Finishing Department have been globally used for smartphones, computers, cars, consumer electronics, computer network servers and other many purposes.

Especially, we have rich and many experiences of the surface treatments in aluminum. OKUNO is an only one company in the world that can provide any of the chemicals for aluminum finishing from pre-treatments to post-treatments. We create new values by supplying aluminum dyes, texture improvers, hand touch improvers and a lot of various chemicals for aluminum as total process.

OKUNO can present infinite possibilities for your tiny little ideas. We will quickly respond to any of your inquiry to transform your ideas into mass-production.

Our research and development is based on the concept of REDUCE, REUSE, RECYCLE.

We are committed to propose the leading-edge, eco- and human friendly technology toward circular economy.

X-ray Photoelectron Spectroscopy

Pulsed Radio Frequency Glow Discharge Optical Emission Spectrometry

History (Metal Finishing)

- 2013

-

Started manufacturing and sales of process chemicals for chromium-free etching for plating on plastic

- 2014

-

Started manufacturing and sales of chemicals for plating on plastic to realize high corrosion resistance

- 2016

-

Established Advanced Technology Research Center

- 2017

-

Started manufacturing and sales of chromium-, palladium-free etching process products for plastic that can shorten treatment steps significantly

- 2019

-

Started manufacturing and sales of electroless copper plating process that can increase the reliability of semiconductor packages (OPC FLET PROCESS)

- 2023

-

As a new brand of surface treatment products for semiconductor back-end processes, released "TORYZA EL PROCESS" series and "TORYZA LCN" series

OKUNO’s strength in metal finishing

Launch of the new brand "TORYZA" for surface treatment chemicals

We offer advanced surface treatment chemicals, such as via-filling additives for acid copper plating, ideal for fabricating high-performance and multi-functional IC substrates.

Presenting our latest brand "TORYZA" for surface treatment chemicals in the semiconductor backend process, we address various requirements, including plating chemicals for ultra-fine patterning and equipment for UBM formation.

Create new values in your products

OKUNO is pursuing metal finishing, surface finishing products and services from pre-treatment to post-treatment all the way to meet ant of customers’ requests. OKUNO offers a wide range of products for fine circuit pattern formation for PWBs, high density PWBs, rust prevention of metals, plating on plastic, aluminum anodizing and coloring for smartphones, aluminum texture improvements and various metal finishing. By the metal finishing and surface treatments for any of metals, ceramics, plastic, we create new and added values for our customers' products.

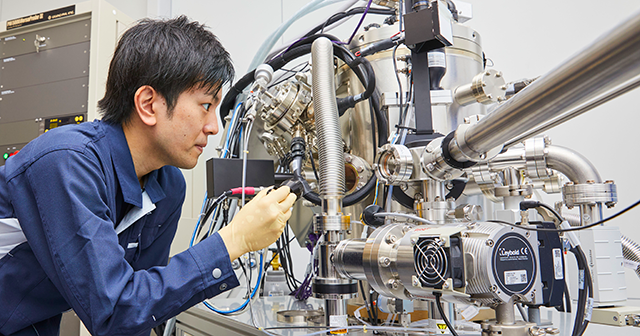

Design total process from prototype to mass-production

The materials and required specifications for smartphones, cars, and semiconductors are changing by the minute. Advanced Technology Research Center located in Osaka, Japan has open laboratory spaces to design total process, make prototypes and evaluate trial samples with our customers. Also, we have pilot lines in the center to conduct metal finishing and surface finishing tests using your samples and actual products. OKUNO can quickly respond to any problems to find the best solution together.

SDGs actions for metal finishing

Our researches and developments are based on the company policy of "Think ECO!".

We have focused on eco- and human-friendly products not using environmentally hazardous substances such as chromic acid, cyanides, lead, PFOS, and PFOA.

Now, we all strive to meet the challenges of new plating processes for 5G and 6G network system to contribute Society 5.0. Furthermore, our researches and developments are continuously evolving for the next-generation mobility to realize carbon neutral.

Trial Production

OKUNO is always challenging to create innovations in surface finishing technologies for various materials from metals, plastic, ceramics to fibers.

We're focusing on customer satisfaction so more than 30% of OKUNO's employees are working for Advanced Technology Research Center located in Osaka, Japan.

In the center, plating on plastic or printed wiring boards, roll to roll electroless plating, anodizing can be conducted with us using many pilot lines.

From developments, trial production to mass-production, our well-experienced staff will certainly help you to find the best processes and solutions especially for you.

Please feel free to contact us at any time from the web inquiry form.

Pilot Line

Laboratory